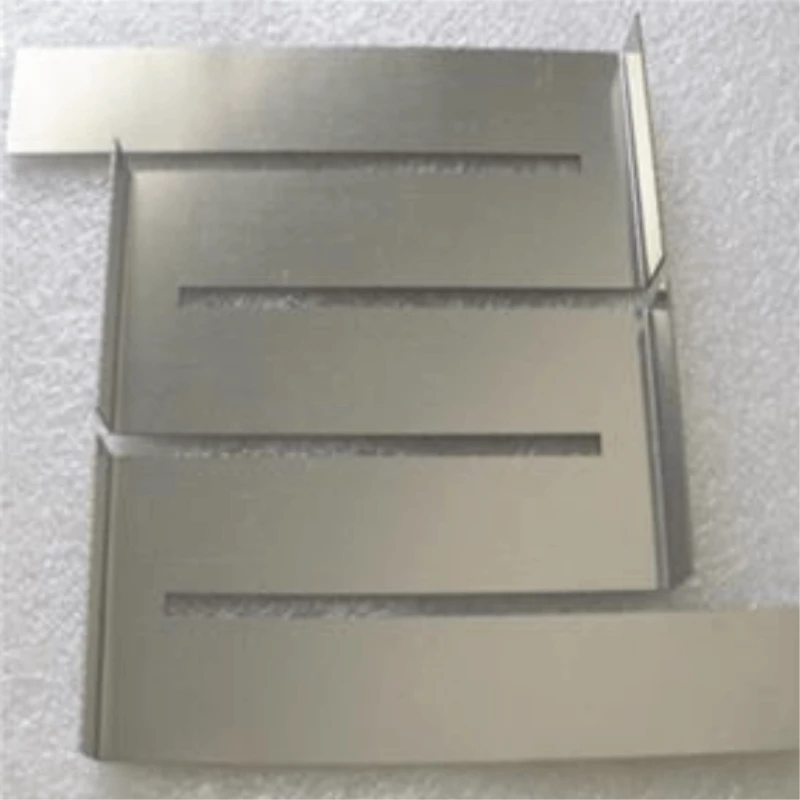

Zhuohangxin Metal utilizza polvere di molibdeno di alta qualità per elaborarlo in lastre con prestazioni eccellenti. Utilizza la tecnologia di laminazione speciale per produrre una serie dipiastra di molibdeno(Foglio di molibdeno) prodotti con i vantaggi di buone prestazioni di lavorazione e superficie liscia.

MO1, MLa

norma: ASTM B386-91,

Purezza: molibdeno puro Mo1≥99,95%, molibdeno-lantanio lega MLa (contenuto di lantanio 0,4-0,8%)

Densità: ≥10,2g/cm3

Ambiente applicabile e temperatura massima applicabile: molibdeno puro entro 1400℃, lega molibdeno-lantanio entro 1800℃ sotto vuoto o ambiente di protezione del gas inerte.

Classificazione superficiale: 1) superficie alcalina laminata a caldo 2) superficie luminosa laminata a freddo 3) superficie lucida

Stato di fornitura: duro o morbido

Specifiche di fornitura:

Foglio: spessore 0.025-0.09mm, larghezza 30-100mm, lunghezza > 500mm

Foglio: spessore 0.09-0.5mm, larghezza 30-600mm, lunghezza 30-2500mm

Piatto: spessore 0,5-10mm, larghezza 50-680mm, lunghezza 50-2500mm

Blocco: spessore > 10mm, larghezza > 20mm, lunghezza>20mm

Flusso di processo: laminazione a caldo--ricottura di sollievo dallo stress--laminazione calda--ricottura di sollievo dallo stress--lavaggio alcalino--primo laminazione a freddo--ricottura di sollievo dallo stress--secondo laminazione a freddo--ricottura di sollievo dallo stress--ricottura di laminazione a freddo del prodotto finito--taglio--ispezione e stoccaggio

Applicazione: Dopo l'elaborazione di rotolamento con una deformazione di oltre il 60%, la densità dello strato di molibdeno è fondamentalmente vicina alla densità teorica. Pertanto, ha alta resistenza, struttura interna uniforme e resistenza di scorrimento eccellente ad alta temperatura. È ampiamente usato nella produzione di schermi riflettenti in forni di crescita di cristallo zaffiro, schermi riflettenti in forni a vuoto di copertura, nastri riscaldanti, connettori, bersagli di sputtering per rivestimento al plasma, barche ad alta temperatura e altri prodotti.

Le piastre sottili laminate a freddo sono utilizzate principalmente nelle industrie elettriche del vuoto e delle sorgenti luminose. Sottileplacche di molibdenoSono trasformati in prodotti di varie forme e specifiche attraverso processi di formatura secondari come il disegno profondo, il disegno e la filatura, come crogioli di molibdeno, barche sinterizzate, anodi ad alta potenza di emissione e cilindri di molibdeno griglia. Con lo sviluppo delle moderne industrie ceramiche ad alta temperatura e dell'elettronica, la domanda di lastre di molibdeno laminate a freddo è aumentata e i requisiti di qualità sono molto severi.

Abbiamo più categorie per te. Se non riesci a trovare i prodotti che desideri sopra, compila il modulo e dicci quali prodotti desideri importare dalla Cina.